Understanding Plastic Mold Manufacturers: Innovating for a Sustainable Future

In today’s fast-paced and ever-evolving landscape of manufacturing, plastic mold manufacturers play a critical role in supplying the essential components needed across numerous industries. From automotive parts to consumer goods, injection-molded plastics have become a cornerstone of modern production systems. This article aims to uncover the intricate processes and considerations involved in plastic mold manufacturing, emphasizing the significance of innovation and sustainability in this sector.

The Core Role of Plastic Mold Manufacturers

Plastic mold manufacturers are specialists who create molds used in producing plastic parts through various molding processes such as injection molding, blow molding, and rotational molding. But what exactly do these professionals do, and why are they essential?

Defining the Manufacturing Process

At its core, the process of plastic molding involves several key stages:

- Design and Prototyping: The journey begins with conceptualizing designs that are often iterative. Engineers and designers collaborate to create a prototype of the final product.

- Mold Creation: Once the prototype is finalized, a mold is crafted from high-quality materials, often steel or aluminum, ensuring durability and precision.

- Injection: During the manufacturing phase, heated plastic pellets are injected into the mold, where they take shape and harden.

- Finishing: After removal from the mold, components are often finished through machining or additional processing, achieving the desired specifications.

Advantages of Utilizing Plastic Mold Manufacturers

The choice to work with professional plastic mold manufacturers offers numerous advantages that can significantly contribute to the success of a business:

- Cost Efficiency: Utilizing expert manufacturers allows companies to benefit from economies of scale, reducing the per-unit cost of production.

- Quality Assurance: Reputable manufacturers adhere to stringent quality control processes, which helps ensure product consistency and reliability.

- Rapid Prototyping: Skilled manufacturers can quickly produce prototypes, facilitating faster iterations during the product development phase.

- Expertise and Support: Partnering with seasoned professionals provides access to industry knowledge and ongoing support throughout the manufacturing process.

Innovative Techniques in Modern Plastic Molding

Plastic mold manufacturers are at the forefront of several innovative techniques that serve to enhance efficiency and product quality. Here are some cutting-edge practices reshaping the industry:

3D Printing in Mold Design

One of the most significant advancements in recent years is the integration of 3D printing technology into mold design. This approach allows manufacturers to create intricate mold geometries that were previously impossible or cost-prohibitive using traditional methods. The benefits include:

- Reduced lead times for mold creation.

- Greater design flexibility, enabling customization for specific part requirements.

- Minimized material waste, aligning with sustainable practices.

Use of Advanced Materials

With advancements in materials science, modern plastic mold manufacturers are now able to utilize high-performance materials that increase mold longevity and efficiency. Some examples include:

- Steel Alloys: Offer increased durability and resistance to wear during the molding process.

- Composite Materials: Provide lightweight options without compromising strength.

- Bio-based Plastics: Support sustainability initiatives by utilizing renewable resources.

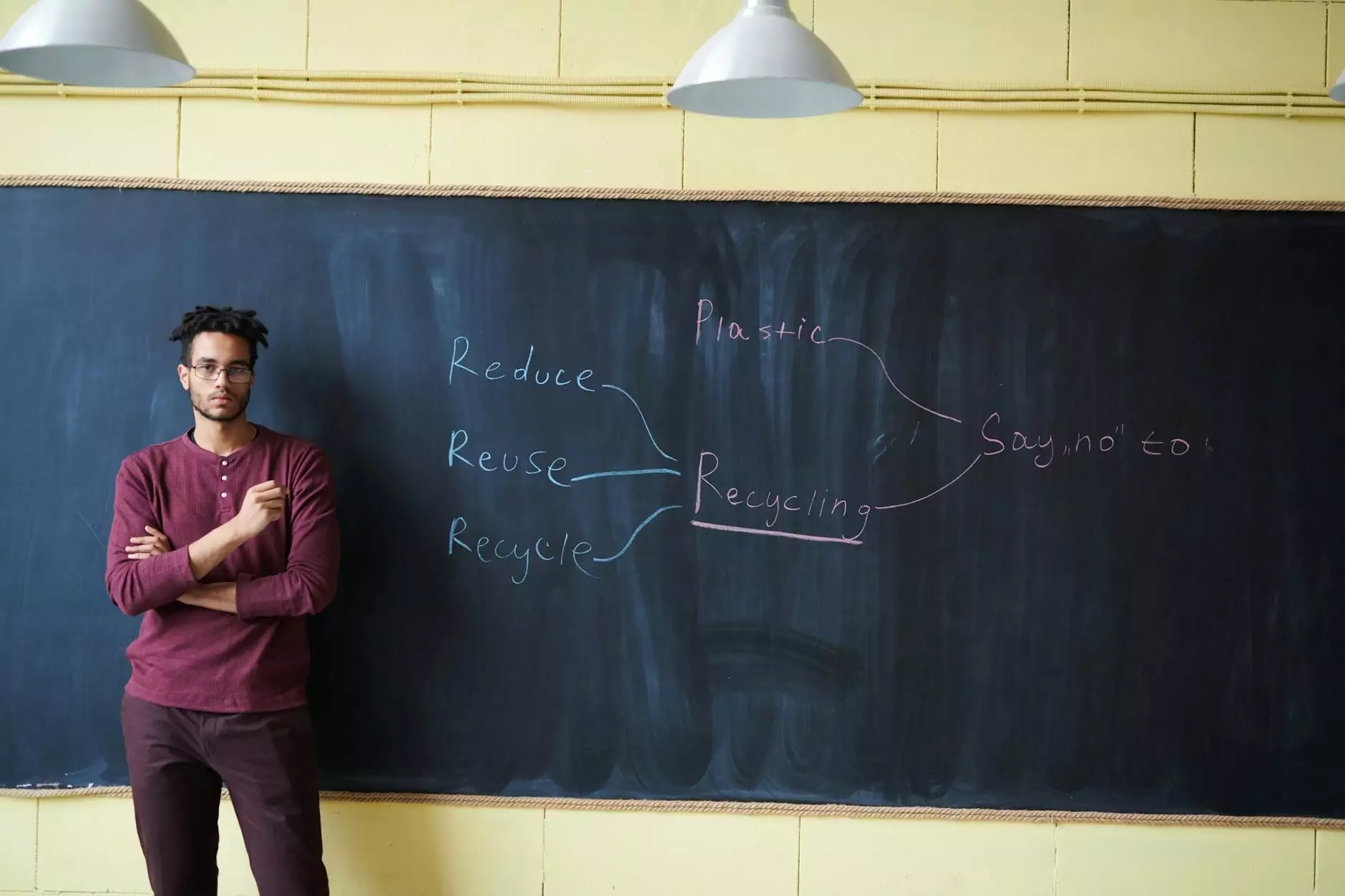

Sustainability in Plastic Molding

The conversation around sustainability is paramount in today’s manufacturing landscape. Plastic mold manufacturers are increasingly adopting practices that emphasize environmental responsibility:

Recycling and Reuse

Many manufacturers are now utilizing recycled plastics in their processes, effectively reducing the demand for virgin materials and minimizing waste. Additionally, it is common to see efforts toward:

- Implementing closed-loop systems where scraps from the production process are reincorporated.

- Designing product lines with recyclability in mind, ensuring that end-of-life products can be easily processed.

Energy Efficiency Measures

Manufacturers are also investing in energy-efficient equipment and practices, including:

- Using machinery that consumes less energy while maintaining high output.

- Optimizing production processes to minimize energy consumption during peak hours.

Choosing the Right Plastic Mold Manufacturer

Finding the right plastic mold manufacturer can be a decisive factor in the success of your project. Here are some essential criteria to consider:

Experience and Expertise

Look for manufacturers with a proven track record in the industry. Their experience often translates to an understanding of complex challenges and effective solutions.

Technological Capabilities

Evaluate the technologies and methods the manufacturer employs. Cutting-edge facilities with modern machinery will likely yield superior results.

Quality Certifications

Ensure that the manufacturer holds relevant quality certifications, such as ISO 9001, which indicates adherence to international quality management standards.

Future Trends in Plastic Molding

The plastic molding industry is continually evolving, and several trends indicate where it is headed in the coming years:

Increased Automation

As industry 4.0 advancements gain traction, automation within manufacturing processes is likely to increase, leading to higher efficiency and reduced human error.

Intelligent Data Management

Implementing smart technologies, including IoT (Internet of Things), will enable manufacturers to collect and analyze data in real-time, leading to more informed decision-making and predictive maintenance.

Conclusion

Plastic mold manufacturers are pivotal to the world of manufacturing, supplying essential components that are integral to countless products. By focusing on sustainability, innovation, and quality, these manufacturers ensure that they not only meet the demands of today but also pave the way for a more sustainable future. As businesses continue to look for efficient and responsible production methods, partnering with capable and forward-thinking plastic mold manufacturers will undoubtedly prove advantageous.

For businesses seeking reliable manufacturing partners, DeepMould.net stands out as a leader in the industry, providing cutting-edge solutions tailored to the evolving needs of the market.